There are three primary steps we use to develop a product, and each plays a vital role in ensuring the success of the project. Though each project may be different with a unique set of challenges, this process is applied every time with positive results.

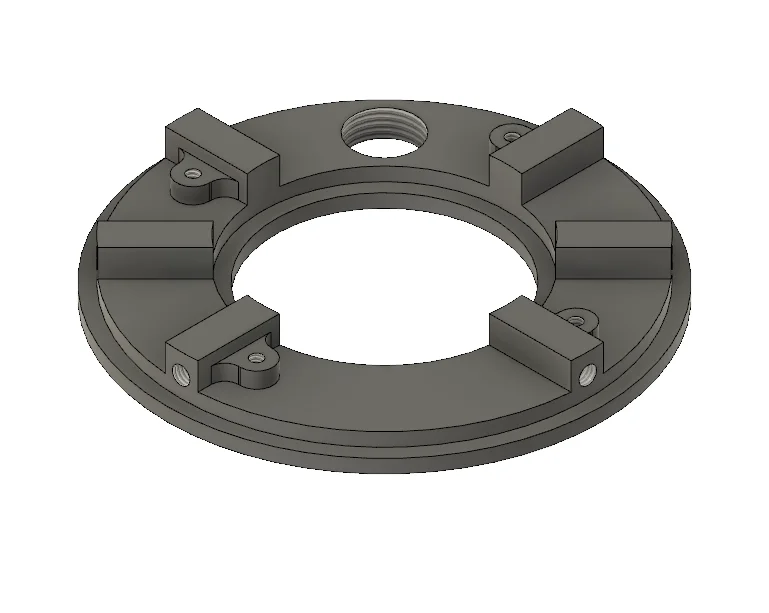

Design

By the end of this stage, the physical attributes of the design are well-defined.

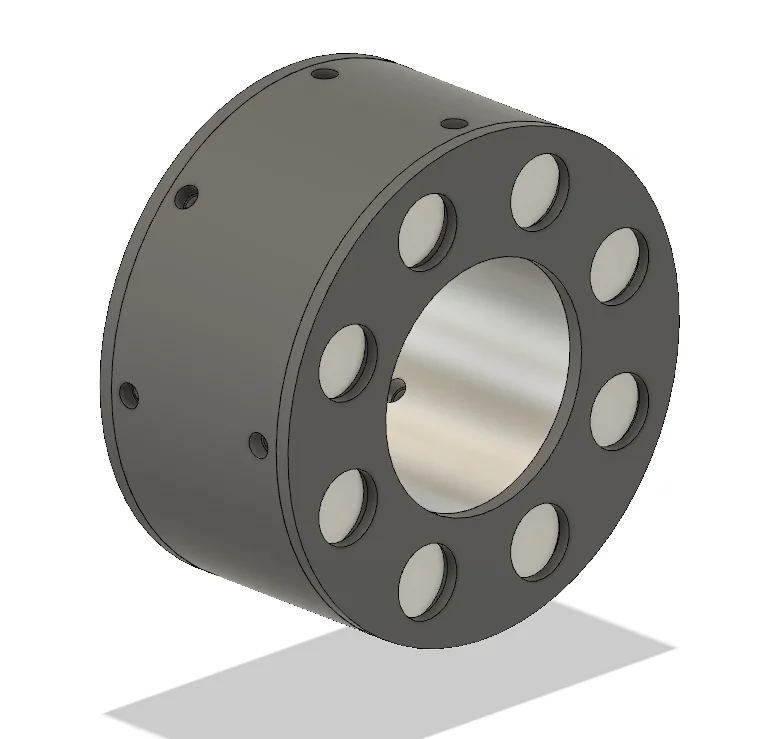

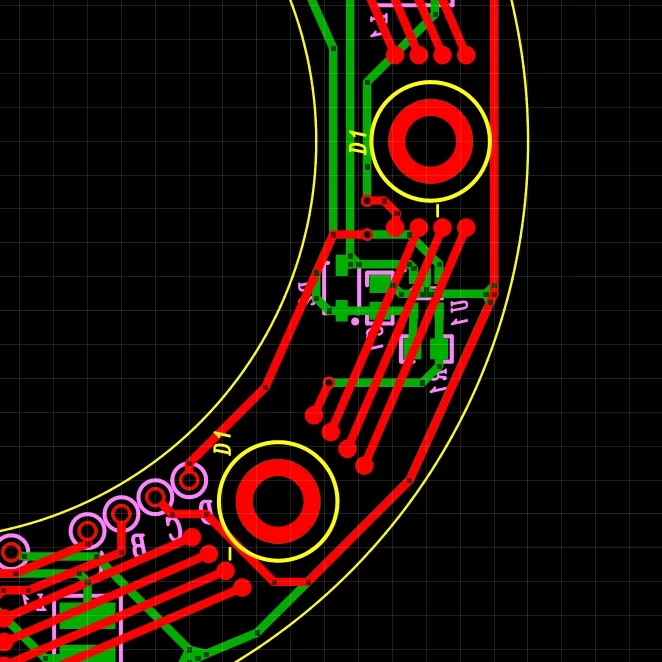

Engineering

Once the design has been finalized, we move into the engineering phase.

|

||

|

|

|

|

|

Where the design stage concludes with a well-defined representation of the end product, the engineering stage concludes with a refined understanding of exactly how the product will work and how it will be manufactured.

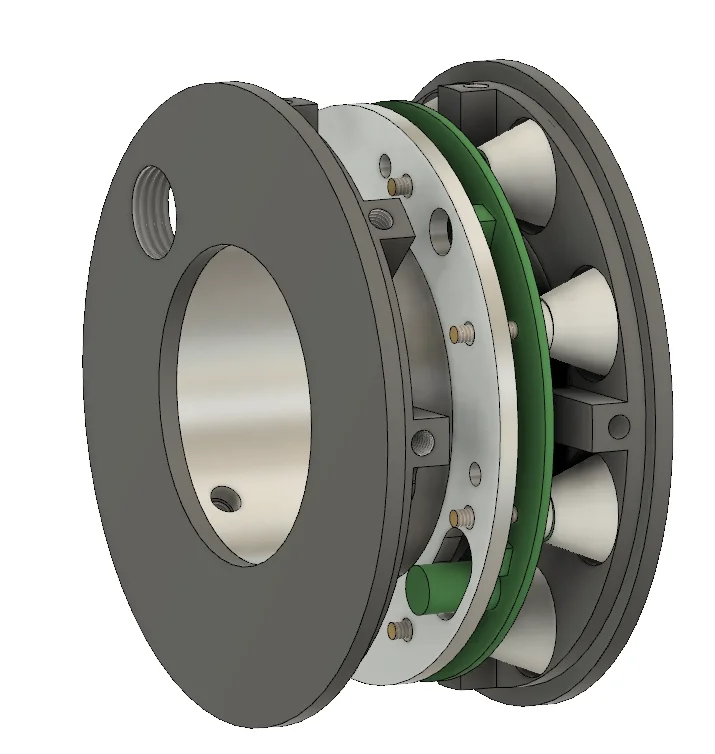

Manufacturing

In this final stage, we create the product using a wide variety of tools and processes.

|

||

|

|

|

|

|

At this stage, the product is complete and ready for use, whether it has a future as a tool for your business, or as a representation to be demonstrated before potential investors.